Equipment inspections at work are a legal requirement. But what does this mean? Some equipment needs a quick check over by the user before use but others need a qualified person to certify it. In this article, I’ll explain what you need to do.

But First, The Law Regarding Equipment Inspections

The Health and Safety at Work Act requires the employer to “Provide and maintain plant, equipment and systems of work that are safe and without risks to health“. The way to do this is by performing equipment inspections.

Three more pieces of legislation support this requirement:

- The Electricity at Work Regulations

- PUWER – The Provision and Use of Work Equipment Regulations

- LOLER – The Lifting Operations and Lifting Equipment Regulations

Let’s look at each one in turn.

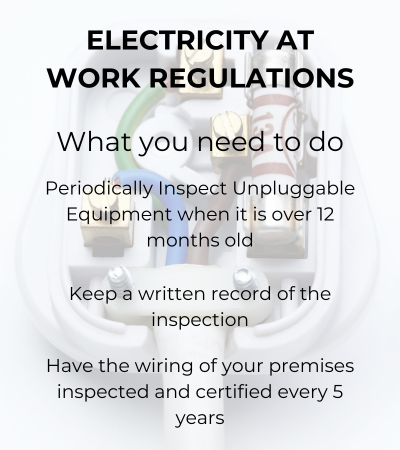

The Electricity at Work Regulations

For the general construction subcontractor there are two responsibilities:

- If you have an office, have the electrical installation, ie the wiring, checked and certified every 5 years

- Have all your portable (ie unpluggable) electrical equipment Portable Appliance Tested. “How often” I hear you ask! The regulations state equipment must be tested periodically. There is no stated time period, it is open to interpretation.

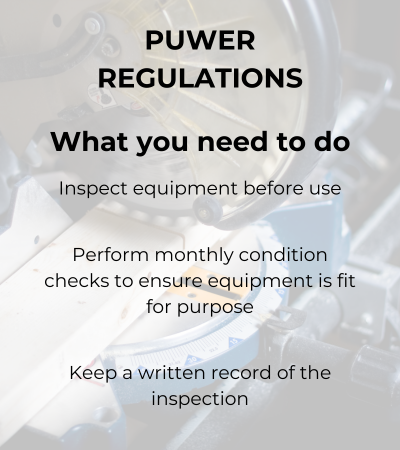

What Does PUWER Stand For?

The Provision and Use of Work Equipment Regulations and for this one there are again, two responsibilities:

- Inspect Work Equipment before use and monthly

- Record the monthly inspection on a form which you will keep for at least three years.

So, What Does LOLER Stand For?

LOLER is the Lifting Operations and Lifting Equipment Regulations, so not applicable to every subcontractor because they don’t all have lifting equipment.

Trades such as groundworkers must comply with the LOLER Regulations and anyone using genie lifts or hoists as both are lifting equipment.

The requirements of LOLER are more in depth than PUWER and the Electricity at Work Regulations. A level of training for the inspections is also required. So, what are the inspections?

- User Checks – Pre start checks by the qualified operator, such as a fork lift driver recorded on a daily inspection sheet

- Weekly Checks – Also performed by the qualified operator and recorded weekly on a form like this

- Thorough Inspections – All lifting equipment such as 360 plant, fork lift trucks, mobile elevated work platforms and cranes must be inspected every six month by an independent examiner. The lifting accessories, so the chains and slings, must also be inspected.

How to Record Equipment Inspections

Inspections must be recorded to ensure you have a record. If something goes wrong which results in an investigation or injury claim, you will have to prove that you complied with the law. By recording your equipment inspections on forms and keeping them, you can easily prove this. If you are a retained client, you will have the forms in your forms pack. If you are not and you just need a form, click the relevant link below to purchase the form you need.